| Usage: | Socket Pipe Welding | Warranty: | 1 Year |

|---|---|---|---|

| Working Range: | 25-125mm/75-160mm | Materials: | HDPE,PP,PB,PVDF,PPR |

| Selling Units: | Single Item | Working Temperature: | 180-280℃ |

| Product Name: | Ppr Socket Fusion Machine |

| PRISMA 125/160 | 110 Volt | 230 Volt |

| Compatible diameters [mm]: | Ø 20 ÷ Ø 125/160 | |

| Power supply: | 110 VAC 50/60 Hz | 230 VAC 50/60 Hz |

| Maximum power drawn: (W) | 2000 | |

| Dimensions during transportation l x l x h (mm) | 1460x700x1080 | |

| Dimensions when working l x l x h (mm) | 1500x840x1260 | |

| Mass of complete machine [kg]: | 100 | |

| Box for transport (dimensions) l x l x h (mm) (*) | 1420x820x930 | |

| Box for transport (weight) [kg] (*) | 40 | |

| SERVICE WRENCHES AND ACCESSORIES | |

| 1 | Socket and accessories box |

| 2 | Extensions for jaws diameters Ø 110 ÷ Ø 160mm |

| 1 | Allen wrench 6 mm |

| 1 | T-wrench T 5 mm |

| 1 | Pin for sockets |

| 1 | Pipe support |

| SET OF SOCKETS | ||||||||||

| 25 Ø | 32 Ø | 40 Ø | 50 Ø | 63 Ø | 75 Ø | 90 Ø | 110 Ø | 125 Ø | 140 Ø | 160 Ø |

| DOCUMENTATION |

| User and maintenance manual |

| Declaration of conformity |

| Electric schemes |

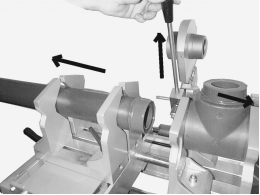

The body consists of four self-centering steel clips for locking pipes and fittings (different brands), self-centering socket welders with electronic temperature control, and equipment. For maximum heating depth, there is a sliding trolley, a tripod for supporting the pipe, a socket and a plug for fused from Ø25 to Ø125 mm or 75-160mm sockets with a steel housing. standard composition-The body is equipped with an electronic socket welder-Steel housing with Ø25 to Ø125 mm socket connector and tool kit- Pipe support tripod- On-demand sliding car

The body consists of four self-centering steel clips for locking pipes and fittings (different brands), self-centering socket welders with electronic temperature control, and equipment. For maximum heating depth, there is a sliding trolley, a tripod for supporting the pipe, a socket and a plug for fused from Ø25 to Ø125 mm or 75-160mm sockets with a steel housing. standard composition-The body is equipped with an electronic socket welder-Steel housing with Ø25 to Ø125 mm socket connector and tool kit- Pipe support tripod- On-demand sliding carThe PRISMA 125/160 is a contact heating plate building-site machine, for socket fusion of polyethylene pipes and fittings (PE), Polypropylene (PP), Polyvinylfluoride (PVDF) and Polybutylene (PB) with a diameter between 25 and 125 mm.

Model PRISMA 125/160 allows the execution of weldings between pipes and fittings, it must be used exclusively by skilled and trained personnel in strict compliance with established legislation.

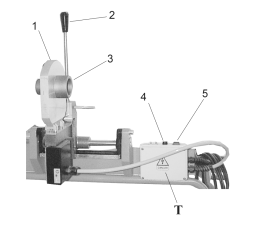

| 1 | Heater |

| 2 | Lever for heater movement |

| 3 | Socket |

| 4 | Fuse carrier |

| 5 | Heater switch |

| T | Thermo regulator |

| 6 | Handle for lifting |

| 7 | Diameter selector |

| 8 | Locking lever |

| 9 | Jaw |

| 10 | Hand-wheel for carriages forward movement |

| 11 | Button for pipe positioning |

| 12 | Hand-wheel locking/unlocking pipe |

| 13 | Trolley handle |

| 14 | Trolley feet |

| 15 | Trolley wheels |

| 16 | T-wrench 5 mm |

| 17 | Sockets |

| 18 | Pin for sockets |

| 19 | Allen wrench 6 mm |