| Product Name: | HDPE Electrofusion Fittings Coupler For Water Supply PN16 SDR11 PE100 | Standard: | EN 12201-3:2011,EN 1555-3:2010 |

|---|---|---|---|

| Material: | PE100 Virgin Raw Material | Norminal Pressure: | PN16 |

| SDR: | SDR11 | Port: | China Main Port |

P2:4.7 Pin(4.0 welded bySwitched adaptor) P3:Printed Parameters P4:Embedded copper wire 1)Fusion Pin of Electrofusion HDPE fittings 4.7mm Pin of Electrofusion HDPE fittings produced. Besides switched adaptors for 4.0 Pin supplied to suit claw of 4.0 electrofusion machine. 2)Moulded-in welding parameters Welding parameters as per EN1555 is printed on the fittings, Such as Products’ name,OD(mm),PE100, PN16 SDR11. Bar code is also attached on the electrofusion fittings for scanning. 3)Element&Stops To promote joint quality,all elements are coated with polyethylene before being moulded into the fitting body. All fittings have removable pipe stops.The stops ensure pipes cannot be inserted past the midpoint,but can be removed for use in,for example,repair situations. 4)High quality copper wire embed in the HDPE fittings which haveGood thermal conductivity.

P2:4.7 Pin(4.0 welded bySwitched adaptor) P3:Printed Parameters P4:Embedded copper wire 1)Fusion Pin of Electrofusion HDPE fittings 4.7mm Pin of Electrofusion HDPE fittings produced. Besides switched adaptors for 4.0 Pin supplied to suit claw of 4.0 electrofusion machine. 2)Moulded-in welding parameters Welding parameters as per EN1555 is printed on the fittings, Such as Products’ name,OD(mm),PE100, PN16 SDR11. Bar code is also attached on the electrofusion fittings for scanning. 3)Element&Stops To promote joint quality,all elements are coated with polyethylene before being moulded into the fitting body. All fittings have removable pipe stops.The stops ensure pipes cannot be inserted past the midpoint,but can be removed for use in,for example,repair situations. 4)High quality copper wire embed in the HDPE fittings which haveGood thermal conductivity.| Products name | Electrofusion HDPE Coupler |

| Sizes Available | As below specification sheet in detail |

| SDR | SDR11,SDR17 |

| PN | PN16,PN10 |

| Material Brand | SINOPEC, BASELL, SABIC, BOROUGE etc |

| Executive Standard | EN 12201-3:2011,EN 1555-3:2010 |

| Colors Available | Black color , blue color, Orange or as request. |

| Packing Method | Normal export packing. by carton |

| Production Lead Time | Depending on the order quantity.Normally about 2~3 weeks for 20′ GP, 3~4 Weeks for a 40′GP. |

| Certificate | ISO, CE,BV,Factory Test Report |

| Supply Ability | 100000 Ton/Year |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF,DDU |

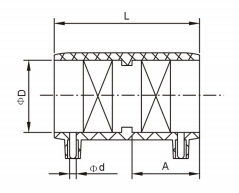

| Specifications φD | L mm | A mm | Φd mm |

| 20 | 85 | 40 | 4.7 |

| 25 | 90 | 43 | 4.7 |

| 32 | 90 | 44 | 4.7 |

| 40 | 95 | 45 | 4.7 |

| 50 | 105 | 50 | 4.7 |

| 63 | 110 | 50 | 4.7 |

| 75 | 135 | 65 | 4.7 |

| 90 | 130 | 63 | 4.7 |

| 110 | 150 | 70 | 4.7 |

| 125 | 165 | 80 | 4.7 |

| 140 | 170 | 80 | 4.7 |

| 160 | 180 | 85 | 4.7 |

| 180 | 210 | 100 | 4.7 |

| 200 | 205 | 100 | 4.7 |

| 225 | 220 | 105 | 4.7 |

| 250 | 215 | 105 | 4.7 |

| 315 | 225 | 110 | 4.7 |

| 355 | 265 | 130 | 4.7 |

| 400 | 310 | 1150 | 4.7 |

| 500 | 370 | 180 | 4.7 |

| 560 | 380 | 185 | 4.7 |

| 630 | 430 | 215 | 4.7 |

We can supply ISO9001-2008, BV ,SGS, CE etc certification. All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

We can supply ISO9001-2008, BV ,SGS, CE etc certification. All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.